Seafood Processing: nuggets, patties and whole filets

Processor Opportunity:

With worldwide demand for affordable and healthy protein rising at a rapid pace, Provisur has been at the forefront of helping seafood processors in the Asian market apply our most advanced technology in order to profitably satisfy their customers with high-quality products, produced in high volumes.

Processor Solution:

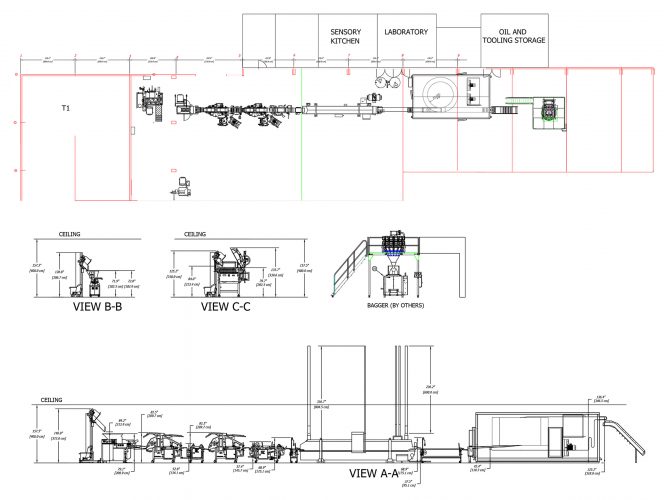

To ensure our customers the ability to produce a wide variety of products from one integrated system, Provisur engineers and applications specialists custom-designed a flexible, high-volume inline system intended to maximize the yield from the Asian carp that are the primary raw material processed. A wide array of machinery from the Provisur family of brands was used to satisfy this interesting challenge. Equipment in this system includes:

- SM820 Separator

- VM36 Vacuum Mixer with load cells and CO2

- F400 Former

- Pre-Duster 400 with cyclone filter

- Coater 400 with 70L batter mixer

- Pre-Duster 400 with cyclone filter

- Combi Dipper with 70L batter mixer

- Fryer 6000 x 400 with oil management system

- Spiral Freezer

This system allows our customer to produce fish nuggets, patties, and whole filets from Asian carp. The nuggets and patties are produced primarily from mechanically separated Asian carp frames that are introduced into the vacuum mixer and mixed with various ingredients, mixed under vacuum and chilled utilizing the bottom injection CO2 system integrated into the vacuum mixer. This material is then transferred to the F-400 former, which forms the appropriate product. The nuggets and patties are then battered, breaded, fried, and frozen. Our customer’s high-quality products are widely distributed throughout the Southeast Asian market.