Processor Opportunity:

With labor and feed costs increasing annually, processors throughout the world are constantly looking for ways to maximize carcass utilization while maintaining minimum production costs. After all, beef bones still retain up to 30% meat to bone weight after hand trimming. With both press and rotary technologies within our portfolio of separation equipment, Provisur has the ability to custom configure the best system for the applications you have in mind.

Provisur Solution:

Using equipment from our BFD®, AM2C® and Beehive® brands, Provisur engineers and application specialists are routinely able to significantly enhance yields, reduce labor costs and satisfy product safety concerns, through custom design of modular, integrated systems.

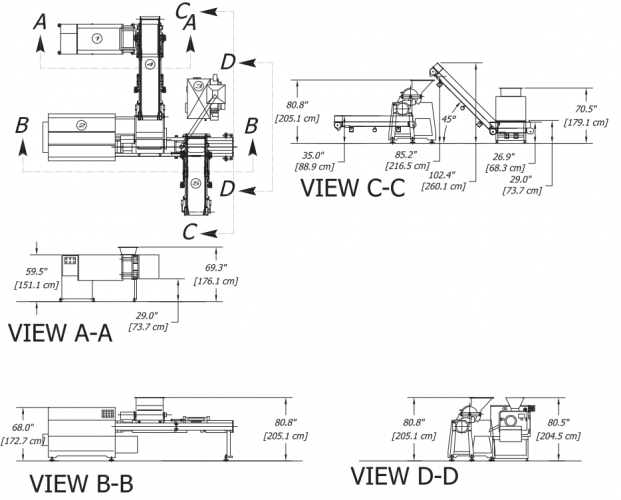

The effective meat recovery system illustrated below uses our revolutionary Bone Cannon™ technology to help achieve our customer’s processing goals. Hygiene and product safety were also assured by a design that eliminates human contact with the product.

Equipment in this system includes:

- PS600 Pre-sizer (Sizes the bones for additional throughput to Bone cannon)

- HS250HP Bone Cannon™ (Extracts additional meat from bones)

- 24TC x13’ Dogleg cleated transfer conveyor (transfers bones from presizer to Bone cannon)

- 24TC x 8’ transfer conveyor (transfers bone cake (residue) to rendering)

Processor benefits gained through the installation of this Provisur technology include a 40% yield increase when compared to manual deboning, as well as significant labor cost savings due the fully-automated features of this equipment. Additional value was gained because the end product from this system can be labeled as trim and mixed with prime cuts to achieve higher profit margins. The mobile, plug and play convenience of installation caused very little disruption in daily operations.