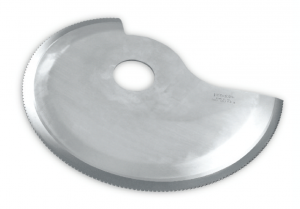

Provisur Tooling & Blades are made from only the finest materials and manufactured to work in complete harmony with your Provisur equipment. Measured and manufactured to work seamlessly with your Provisur equipment, our tooling and blades are crafted from the world’s finest materials, ensuring long life and assisting the production of attractive products and consistently on weight portions. Maximize your machine performance with genuine Formax Blades or any of the vast of combinations of innovative Formax Tooling that can be customized to advance your product development and processing efforts. See details below.

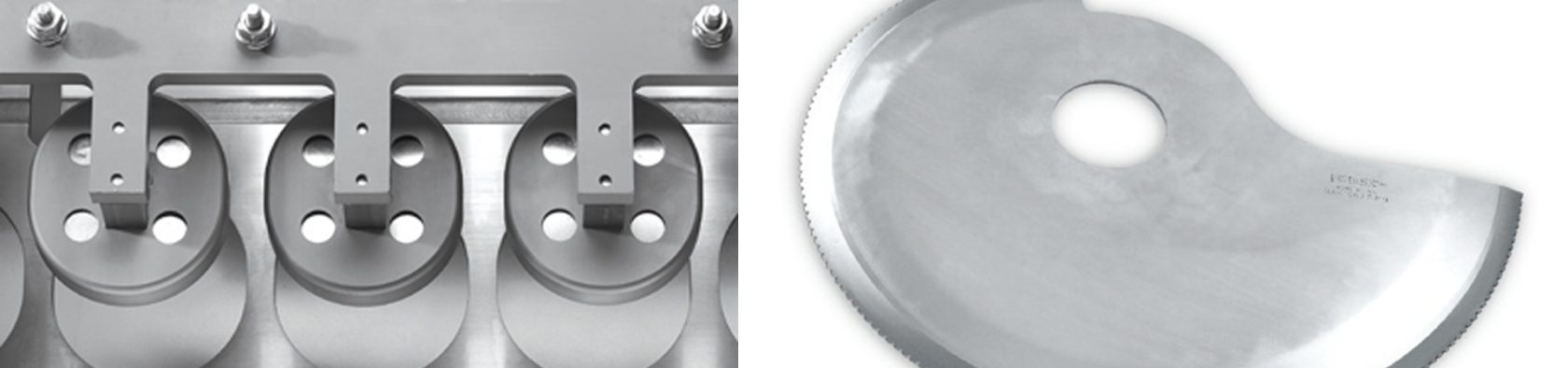

Formax® Forming Tooling

Formax Tooling is measured and manufactured to work with your Formax® forming equipment. Innovative systems for whole muscle poultry, chicken nuggets, boneless hot wings, skinless sausage, bratwurst, and more are made from only the finest materials, including, PerformAlloy®, Formalyte® and EconoTest®. Our tooling is engineered to the tightest tolerances to minimize leakage and maximize usable life. Only Formax Tooling including drums, mold plates and breather plates, can provide you with processing flexibility, while also delivering the industry’s most consistent portion weights and minimal leakage.

Be assured, the Formax tooling group also offers the shortest lead times in the industry and can design customized tooling to help you produce the most demanding 3D product shapes.