Provisur Technologies / Commercial Food Processing Equipment / Frying, Cooking & Smoking / Lutetia® Cookers and Smokers

Maximize versatility and product quality. Lutetia® cookers provide broad functionality.

Whether your process requires wet cooking with steam, dry cooking with heated air or relatively low temperature cooking of previously vacuum-packed products, Lutetia can provide an efficient solution that will help you minimize cycle times, improve product quality and maximize your throughput.

Your versatile Lutetia cooking equipment can also be used to efficiently produce dried and smoked products of consistent quality. Additionally, the Cold Convection functionality built into your Lutetia system will speed defrosting by circulating humid air within the chamber, adding steam and water misting to reduce product drying.

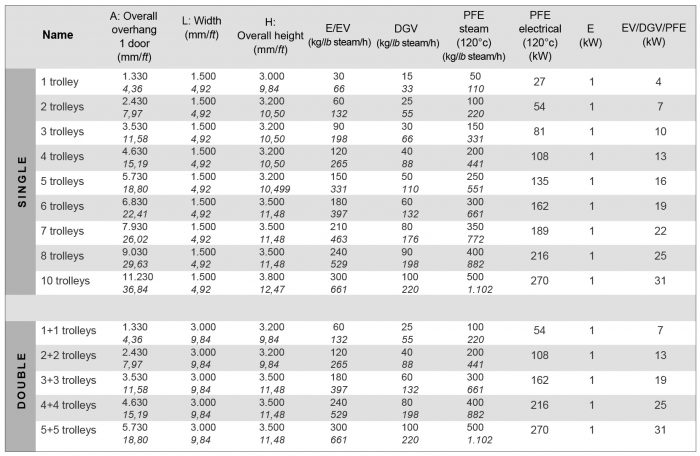

| Configuration options | Chambers are available as single or double chambers. Number of trolleys that can be selected for the single chamber are one through ten. Number of trolleys that can be selected for the double chambers are 1+1, 2+2, 3+3, 4+4, 5+5. For technical specifications, please reference the chart below or the brochure. |

|---|---|

| Features | Steam manifold, steam circuit, resistances, turbine, ambient probe and core probe |

| Machine Flexibility | Cookers can be configured for dry, wet and vacuum cooking. |

| Wet Cooking | Injection bars diffuse low-pressure steam directly into the cooker, with a heightened exchange coefficient in the product/steam interface. Steam provides latent condensation heat to the product. |

| Dry Cooking | A tubular exchanger or an electrical resistance in the vault produces dry heated air. The exchange coefficient a the product/dry interface is lower. |

| Vacuum Cooking | Consists of cooking a previously vacuum packed product at a relatively low temperature. The product is pasteurized in its final packaging and its cooking performance is optimized. |

| Optional Smoke Generators | Other generators available include Sawdust, Woodchip, Log and Liquid Smoke generators |