Only Provisur offers processors the choice of all three mechanical deboner and desinewer separation machines (rotary, belt and press technologies) to match the exact need for output texture and quality, as well as the cost-efficient recovery of meat, poultry, and other raw materials, including potatoes, fruits and vegetables.

Meat, Poultry and Raw Material Separation

The revolutionary Piranha RSBF separator turns 90-97% of bone collection material into quality ground meat. It efficiently filters the bone from the meat, eliminating unnecessary waste while providing extra product that would otherwise be discarded.

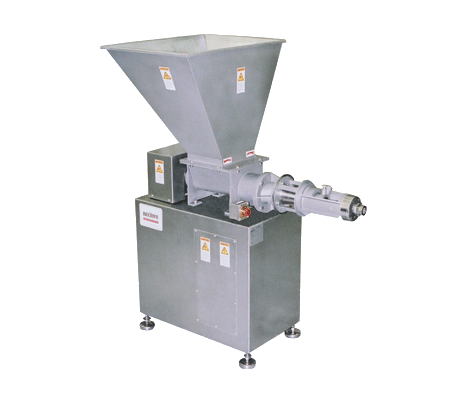

The STS performs high-yield separation of bones and cartilage to ensure higher yields and higher-quality end products. A streamlined configuration makes the STS easy for staff at all levels of experience to disassemble and clean easily.

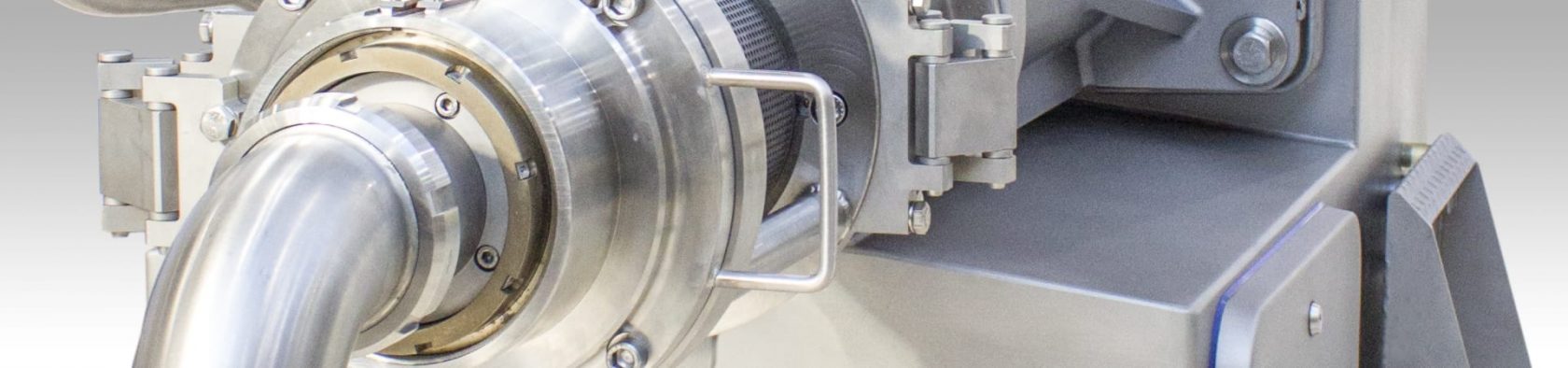

With exclusive features for deboning and desinewing, the RSTC Series separators generate superior quality and texture. The RSTC Series combines stainless steel construction and a powerful feeding mechanism that’s up to your most demanding production requirements.

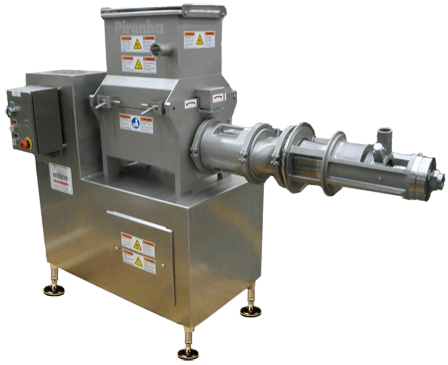

This high-capacity separator is equipped with a 4” (102 mm) plate and twin-screw rotary design that consistently delivers the most premium product texture in the industry. Add unmatched durability to your processing line with the RSDDO4 separator.

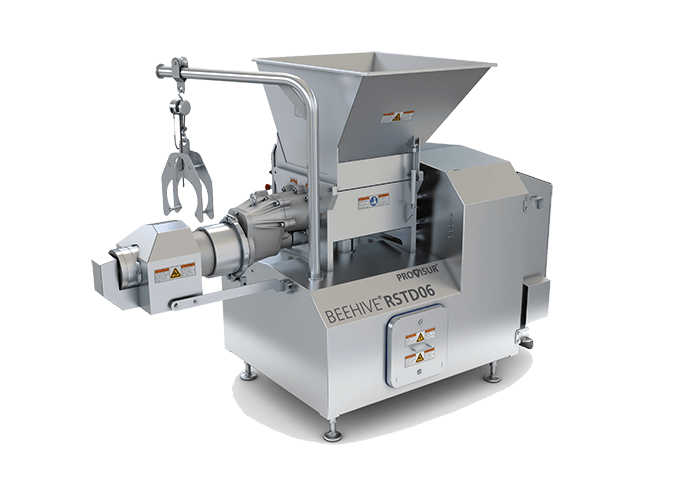

The RSTD06 separator has a unique ability to handle a broad range of raw products that other separators cannot. Precise controls also allow the operator to generate a variety of textures, resulting in extraordinary “bite” and a premium end product.

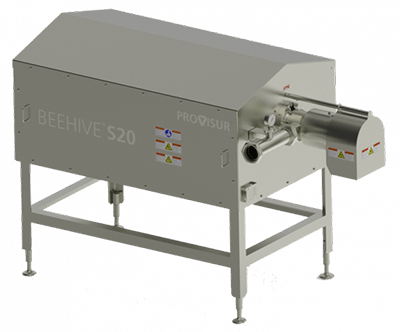

BeeMax separators are engineered to fully maximize your poultry processing operation. New high output chamber configurations and Beehive’s unique modular component concept guarantees superior versatility, excellent product quality and low maintenance costs.

Get higher yields and superior product quality all while lowering operational and maintenance costs. The easy-to-use S20 rotary separator delivers high-speed separation and the highest available yield in the industry.

The RSP-12 potato separator was engineered to efficiently process potatoes. It’s gentle pumping action preserves the integrity of the separated potato product by reducing the number of ruptured starch cells. Get high-yields and a superior end product with the RSP-12.

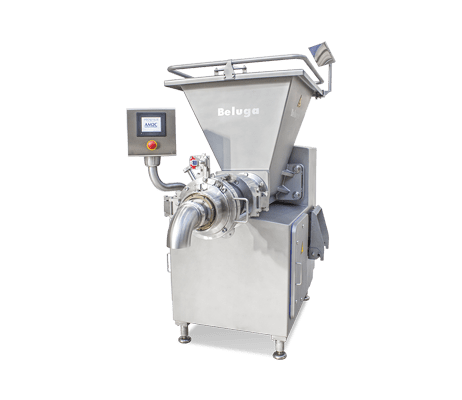

The SD and Beluga® separators can handle your most difficult deboning applications. Their modular systems provide a high quality, ground product while keeping fibers and textures intact. With no pump and only 3 moving parts, maintenance costs are low.

The SM and Barracuda® separators combine the best separation technology from our Beehive® and AM2C® brands. These modular systems provide the highest yield for a multitude of product applications and are designed for greater simplicity and ease of use.

The Pre-sizer ensures a consistent input and product flow to the Bone Cannon® (Hydrau-Separator), increasing throughput by 10%. With minimal moving parts the Pre-sizer provides years of trouble-free service and optimum cleaning and hygiene.

The Bone Cannon® press separator extracts high yields of meat that remain after prime cuts have been harvested. With the Bone Cannon®’s powerful press technology you can maximize your raw material investment while maintaining minimum production costs.

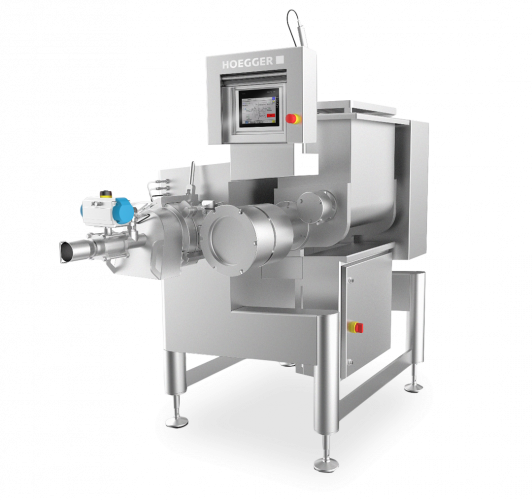

Hoegger™ is renowned for gentle hard/soft separation in applications like potato mash, flakes and formed potato products, as well as fruits and vegetables. PS Series separators are operator friendly, easy to clean, and have very low operating costs.

Ingenuity Center

Bring your product ideas to life at our fully functioning test facility.

Contact Us

Get sales and service support from our global staff of food processing professionals.