As your partner in technology, Provisur® can help with integrated system solutions from our family of proven brands. However, it takes more than just world-class equipment to produce an integrated production line that delivers the performance you need. It requires the experience and application expertise to tailor the system to match your specific needs. It requires proprietary software tools that can model a variety of production scenarios to help determine the combination of equipment that will optimize line efficiencies. And it requires careful planning and coordination to turn the system concepts and designs into a high performing production line in your facility.

Using the proven Provisur family of brands, each piece of equipment builds on the other, resulting in the highest possible quality for your end product and the utmost in throughput efficiency for your production line. We’re here to show you the possibilities.

Food Science Team

Provisur has a team of full-time, degreed food scientists with more than 80 years of combined field experience. This team not only has the theoretical know-how, they have also worked directly in processing plants in a variety of applications, including poultry, pork, beef, and prepared foods. They use this plant experience and their formal training, combined with proprietary software tools, to design better systems for our customers. Our Food Science team will also be available to consult with you long after your line is operational, should you ever need help with production challenges.

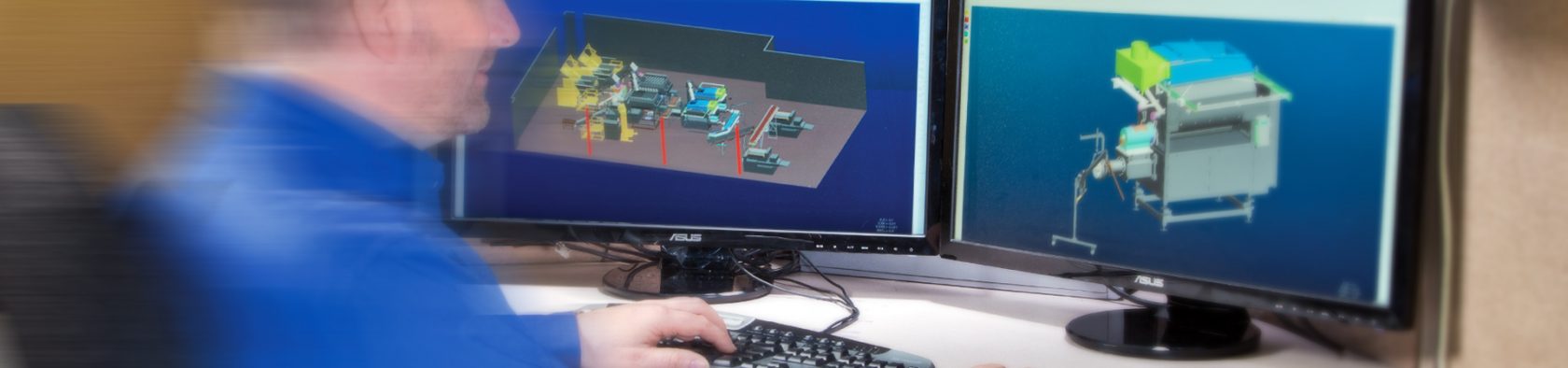

OptiLine System Design

The OptiLine System Design is our process that uses proprietary technology to simulate your production and analyze your operations. We can run multiple production scenarios and line configurations in a relatively short time to determine the best solution. As a result of the OptiLine process, we gain clear insight into your specific needs to allow us to create a customized and integrated food processing system that meets your requirements and optimizes product quality and line efficiencies.

Project Management

A well-designed line configuration is essential to success. However, without careful planning and disciplined execution, the final production line can fall short of your expectations. Provisur actively manages integrated system projects to ensure successful installation and startup on time and to your performance requirements. We utilize proven project management tools to carefully plan, coordinate, and monitor project activity. This includes Project Charters to clearly define the project scope and expectations, as well as Gantt charts to track and manage the project schedule. Periodic updates are provided to the customer to ensure that FATs, installation, commissioning, and startup are fully coordinated.