Retail Bacon Slicing with 3D Scanner

Processor Opportunity:

With demand for their retail bacon products growing, our customer was eager to upgrade their slicing lines to achieve greater throughput, improved yields and higher levels of automated efficiency that would help them better control labor costs.

Provisur Solution:

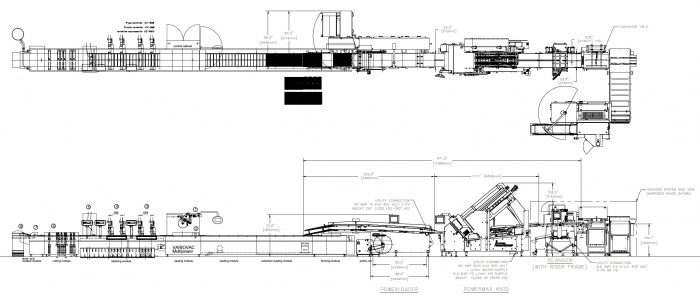

With customer volume and throughput needs requiring high levels of slice quality, along with the ability to slice two bellies at one time, the Provisur engineering and product applications team specified the incomparable Formax® PowerMax® 4500 Slicing system with dual product drives to anchor this high-speed system. To assure upstream efficiency and portion quality, a Hoegger® Form Press was included to automatically feed the two-lane, 3D product scanner that helps ensure product quality and portion consistency, along with minimal giveaway. Equipment in this system includes:

- Hoegger Form Press IP320 with back loader

- Automated conveying system between press and product scanner

- Twin lane product scanner SCN545

- PowerMax4500 Slicing System with dual independent product drives

- 2×2 Autoloading System

Processor benefits gained through installation and use of this efficient and high-powered system include minimal giveaway, consistent slice counts, and precise slice thickness within each individual draft. This result was achieved, in part, through the innovative SCN545 scanning technology that analyzes the shape and weight of each belly. That information is instantly communicated to the PowerMax4500, which automatically calculates the optimal way to slice each belly for best results.

Due to the dual AccuPower independent product feeds, the PowerMax4500 slicer is able to slice two bellies simultaneously while achieving precise weight control on each sliced portion. The two lanes of sliced product are arranged in the proper orientation to match the die set, and then automatically loaded into the packager. The line has been proven to deliver excellent portion control and up to 100 portions per minute while requiring minimal labor.