Retail Bacon Slicing to Roll Stock Packaging

Processor Opportunity:

With high-speed roll stock packaging equipment already in place, this bacon processor relied on Provisur to deliver an automated press to slice solution that would deliver the required throughput and maximize yield, while also minimizing labor costs and product giveaway.

Provisur Solution:

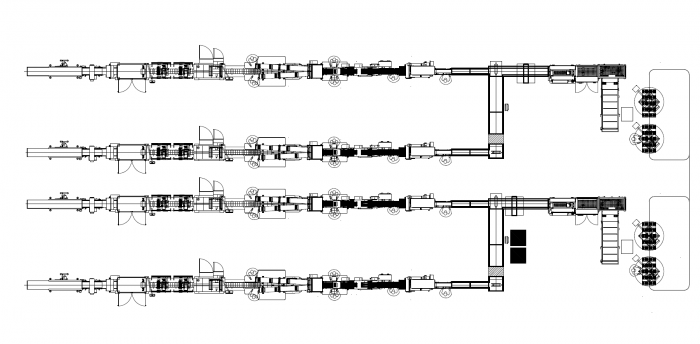

To meet and exceed processor goals, Provisur designed and delivered a retail bacon slicing solution that included, along with efficient transport systems, two powerful Hoegger® form presses that would efficiently feed four high-speed slicing lines anchored by CashinEdge® HS Bacon Slicers with Profile Sensors.

To help optimize yields, Provisur system engineers utilized Hoegger’s unique form press technology to calibrate and shape each belly prior to slicing. To maximize speed and processing efficiency, the intermediate conveying system specified in this system determines when each slicing line requires more pressed bellies and then automatically feeds the appropriate line. Equipment in this system includes:

- Hoegger IP420 Presses (2)

- Automated conveying systems between presses and slicing lines

- CashinEDGE HS Slicing lines (4)

- Each line includes: CashinEDGE HS Retail Slicer, Checkweigher, Load Assist Conveyor

Processor benefits gained through installation of this automated slicing system include optimized yields, lower labor requirements, and less than 1% product giveaway on up to 240 drafts per minute (60/slicer) across the four slicing lines. Load Assist Conveyors facilitate manual loading of the roll stock packager and enable just two operators to effectively load the packager at the high production rates.