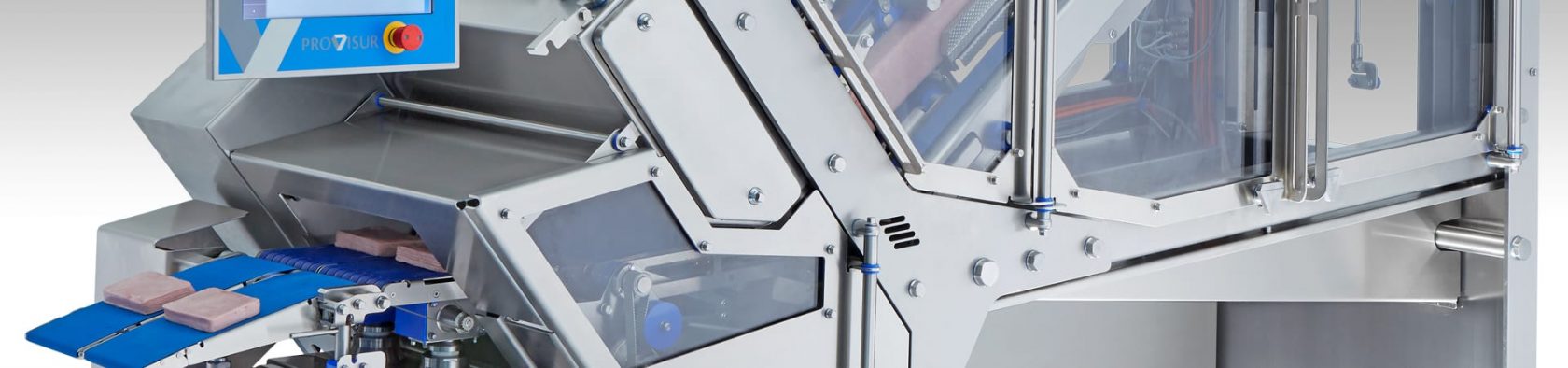

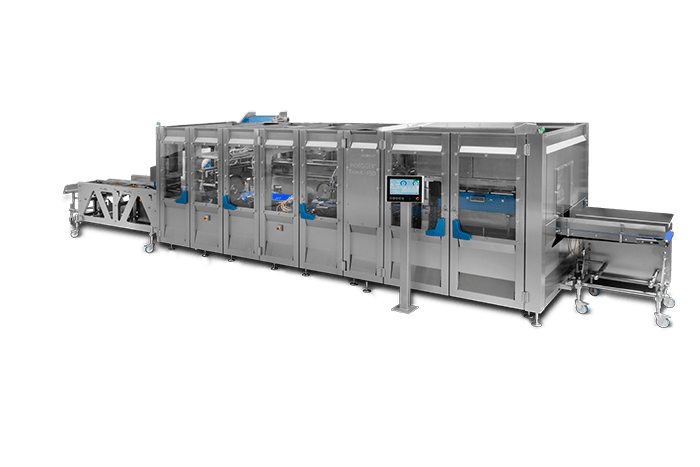

To precisely match your needs for efficiency and throughput, Provisur offers the Formax® brand press-to-slice and slicing food processing equipment for deli meats, cheese and naturally shaped products. Cashin® brand industrial slicers are engineered for high-speed streaky bacon production, in addition to ham, pepperoni and bulk products. For automated pressing and slicing of meat and cheese products, both Provisur brands utilize proprietary technology that’s proven to boost yields, reduce giveaway and enhance food safety.

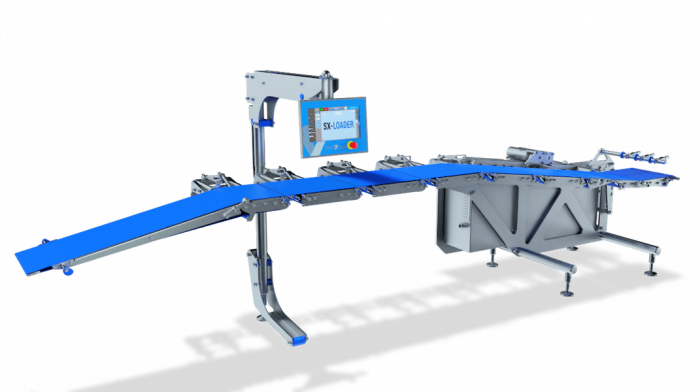

All Formax® and Cashin® industrial press and slicing machines are complemented by the efficiency of our Multitec™ brand of product handling solutions that automate portion handling, minimize labor and optimize food safety.